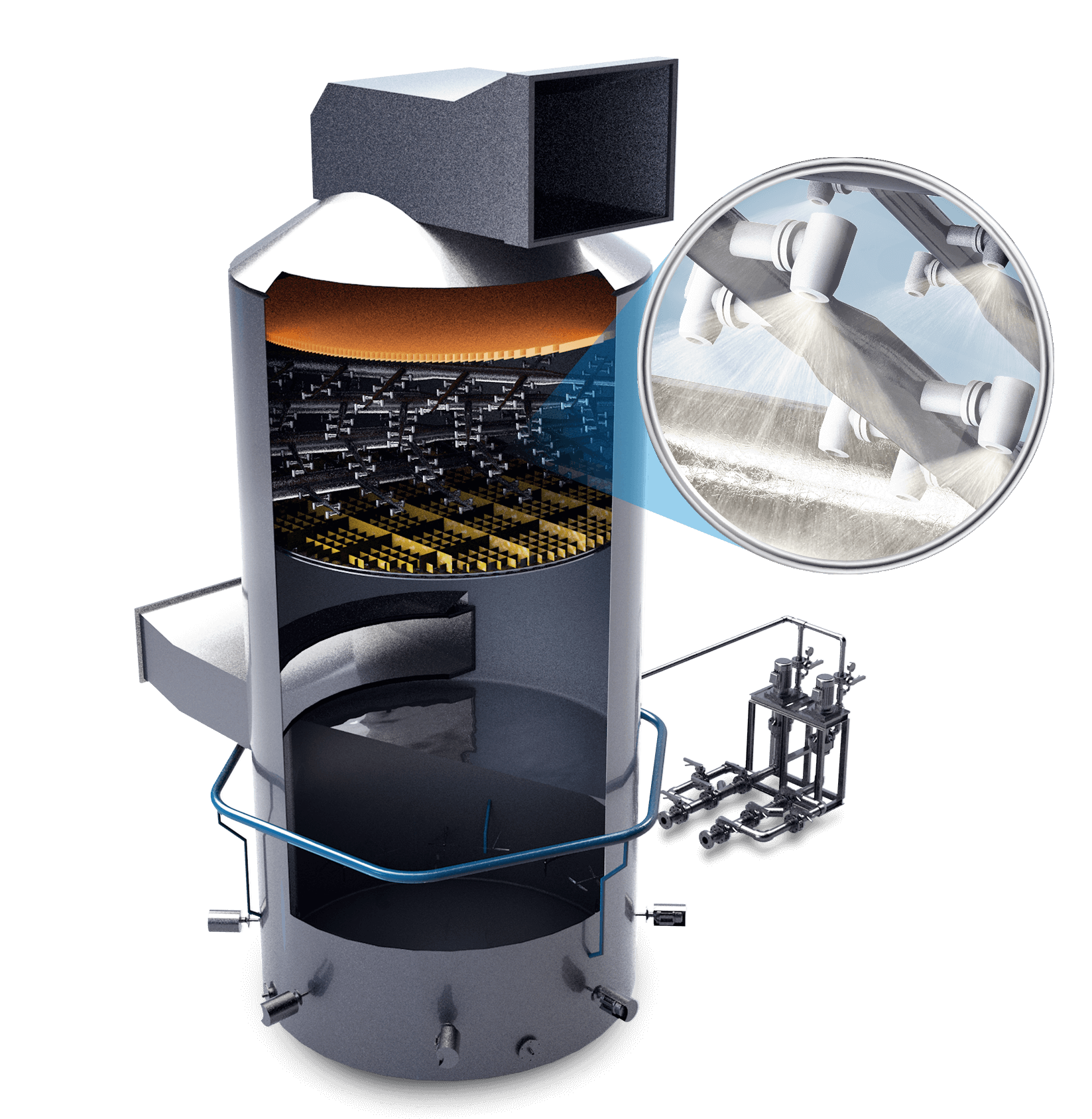

当将化石燃料用于燃烧过程中运行锅炉,炉子或其他设备时,它们可以释放SO2或SO3作为废气的一部分。这些硫氧化物很容易与其他元素反应,形成有害化合物,例如硫酸,并可能对人类健康和环境产生负面影响。由于这些潜在影响,对这种化合物在烟道中的控制是燃煤电厂和其他工业应用的重要组成部分。

由于侵蚀,堵塞和积累问题,控制这些排放的最可靠的系统之一是使用石灰石,水合石灰,海水或其他碱性溶液进行开放式湿烟气脱硫(FGD)工艺。188金宝搏正网喷嘴可以有效,可靠地将这些浆液分配到吸收塔中。通过创建适当大小的液滴的均匀图案,这些喷嘴可以有效地创建适当吸收所需的表面积,同时最大程度地减少磨砂溶液进入烟道气中。

BETE FGD Brochure

Download PDF

BETE FGD Technical Manual

Download PDF

化学加工手册

Download PDF

石化加工手册

Download PDF

Important factors to consider:

Scrubbing media density and viscosity

Required droplet size

- The correct droplet size is essential to ensuring proper absorption rates

Nozzle material

- As the flue gas is often corrosive and the scrubbing fluid is frequently a slurry with high solids content and abrasive properties, selecting the appropriate corrosion and wear-resistant material is important

Nozzle clog resistance

-

- As the scrubbing fluid is frequently a slurry with high solids content, selection of the nozzle concerning clog resistance is important

喷嘴喷雾图案和放置

- To ensure proper absorption, complete coverage of the gas stream with no bypass and sufficient residence time is important

Nozzle connection size and type

Required scrubbing fluid flow rates

Available pressure drop (∆P) across the nozzle

- ∆P = supply pressure at nozzle inlet – process pressure outside nozzle