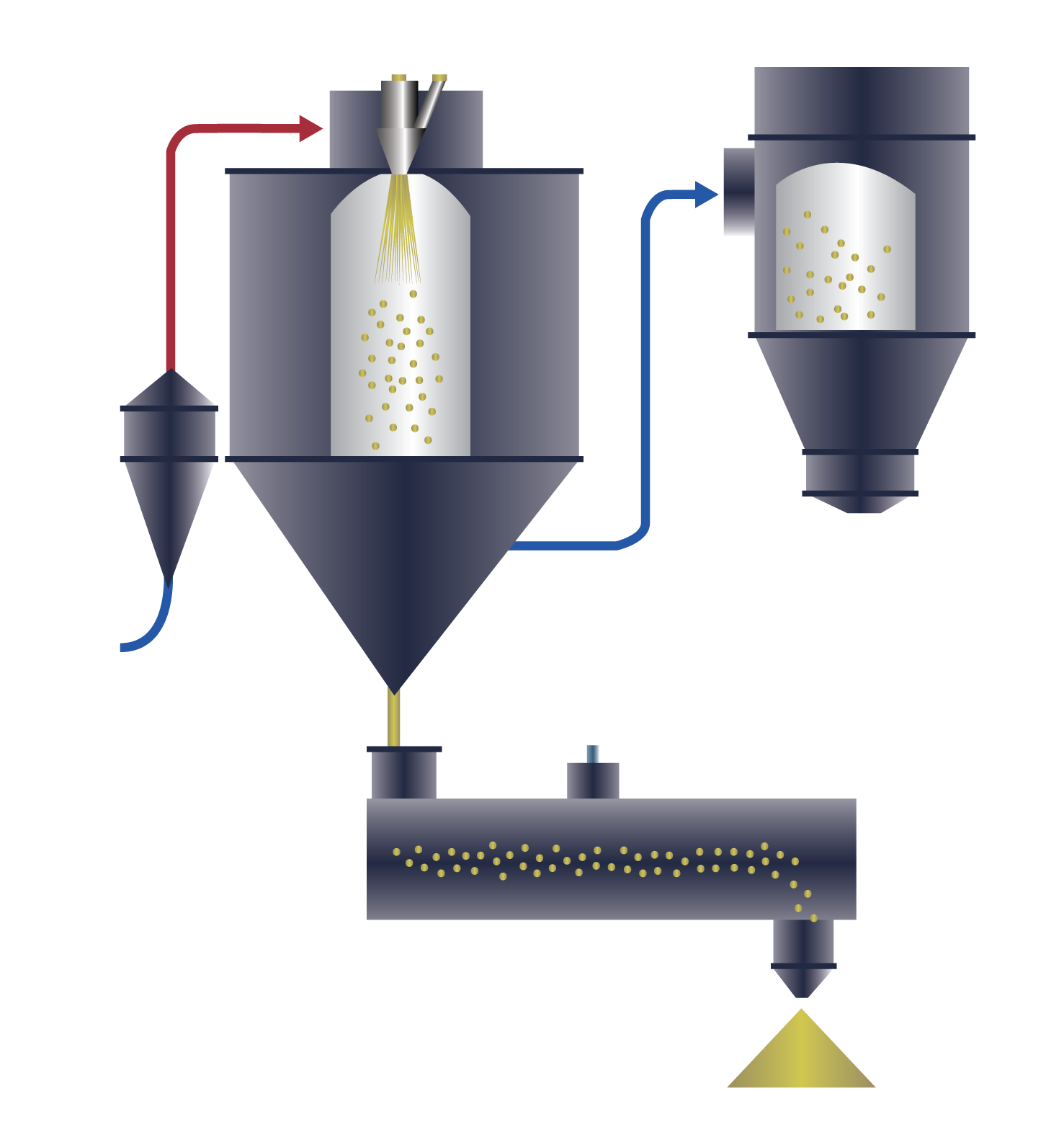

The function of a spray nozzle in a spray dry system is to control the feedstock flow rate and uniformly distribute atomized droplets/particles into the heated drying chamber. Spray dry nozzles typically operate at higher pressures or utilize air atomizing techniques to produce droplets in the 30 – 120 micron range. Surface area is maximized to the volume of the particles, allowing them to dry much quicker than other drying methods. In many dryers, evaporation is 95% complete within seconds.

Specific spray dryer requirements and operating conditions can vary widely across the industry:

- Typical operating pressures can range from 3,000 – 5,000 psi with hydraulic nozzles to achieve the atomization required for effective spray drying. Some products/applications require operating pressures up to 10,000 psi for efficient dryer operation. Air atomizing nozzles can achieve fine atomization at lower pressures between 30 – 100 psi with compressed air or other gas.

- To achieve the evaporation rates required for effective spray drying without damaging the end product, choose operating temperatures between 175 – 450 °F. Some products/applications require up to 600 – 800 °F while incorporating other design features that reduce or eliminate bearding issues.

BETE produces a variety of hydraulic and air atomizing nozzle types, features, and materials to fit your spray drying application requirements. Consistent performance and quality allow for high-quality products through constant particle sizes with even moisture content. High strength, wear-resistance, and high-temperature material options allow for long service life and safe operation within the high pressure, high temperature, and abrasive applications found in the spray drying industry. Replacement orifice discs and swirls are readily available.

Food & Beverage Processing Brochure PDF

Download PDF

BETE Spray Dry Manual

Download PDF

Important factors to consider:

Spray media density, viscosity, solids content, and particulate size

Dryer size, velocity, pressure, temperature, and humidity

Required materials of construction for corrosive environments

Spray media density and viscosity

Required spray media flow rate

Available pressure drop (∆P) across the nozzle

-

- ∆P = supply pressure at nozzle inlet – process pressure outside nozzle