Chemical Inhibitor Injection

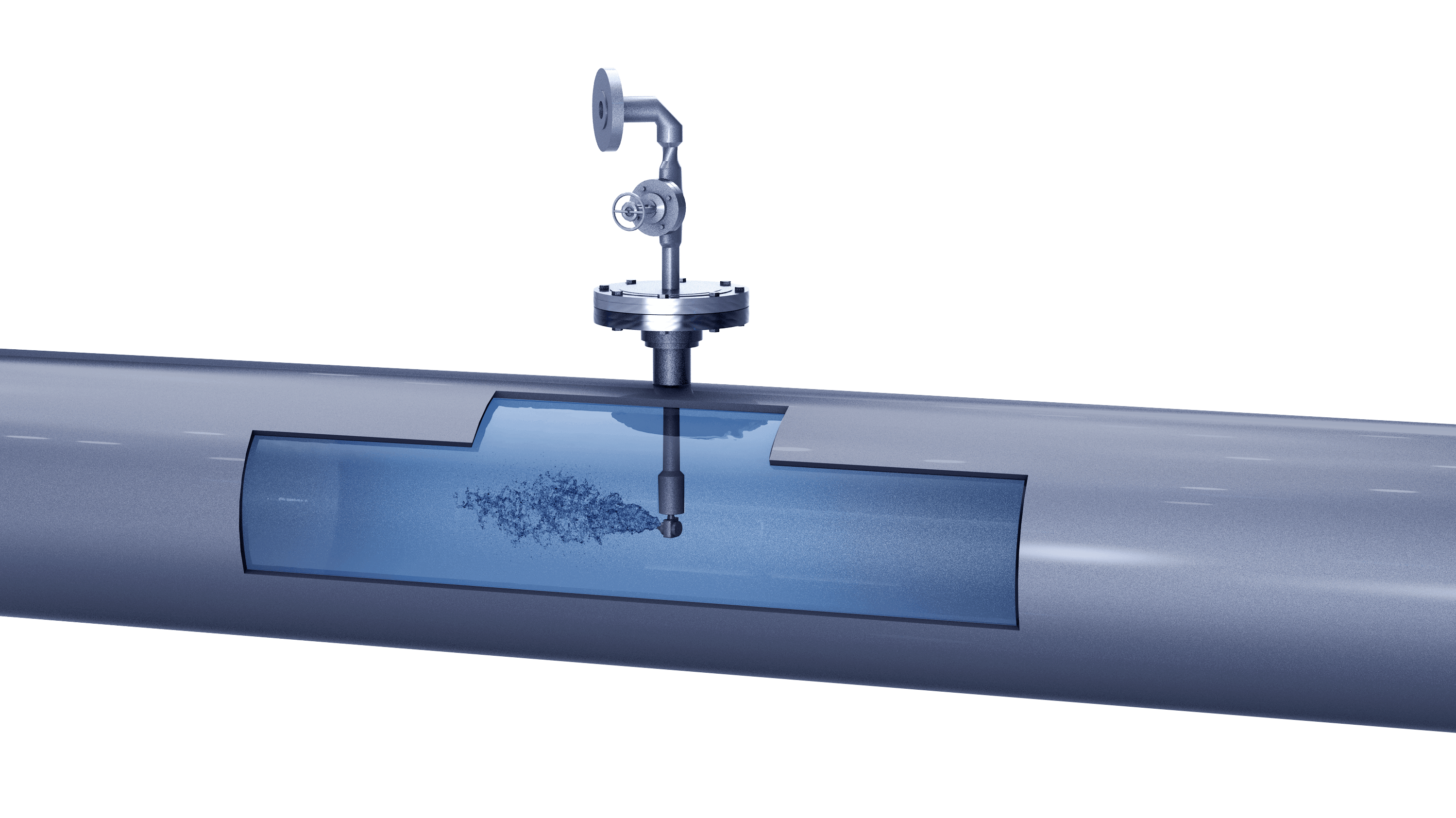

Systems and processes can suffer from performance issues related to corrosion or scale buildup in components such as piping, heat exchangers, pumps, and valves. Corrosive decay can affect the safety and integrity of a system by degrading materials and components. Scale buildup may affect the efficiency of a process by decreasing flow passages and potentially blocking all or part of a process stream. Heavy scale buildup can break off and clog or damage downstream equipment.

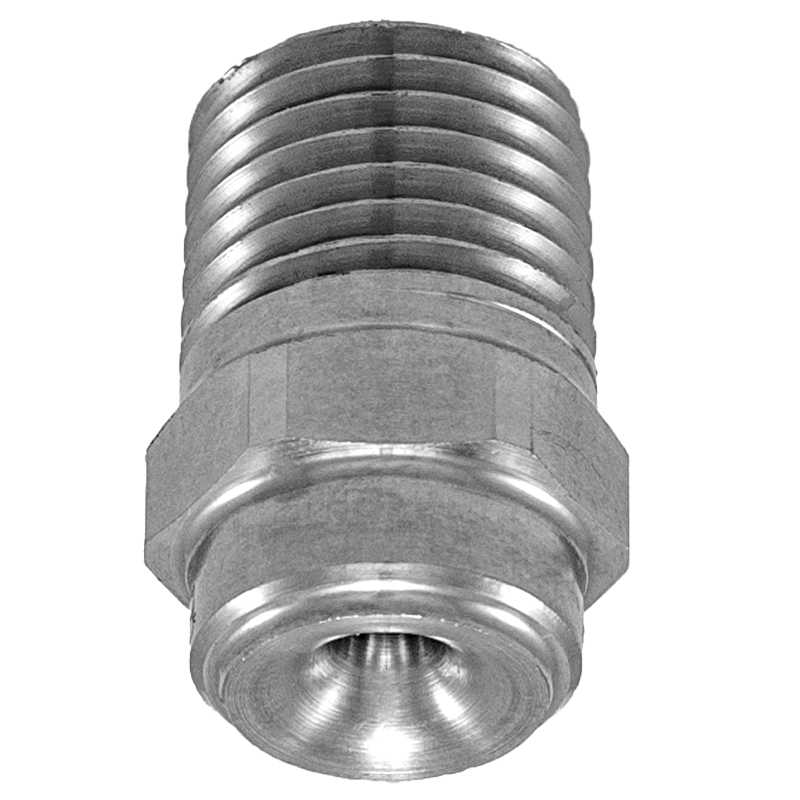

BETE spray nozzles maximize efficiency in inhibitor injection applications as they atomize and distribute the inhibitor liquid into the vessel or process stream to prevent corrosion or scale formation.

Scavenger Injection

Scavengers are liquid chemicals that neutralize and remove small amounts of hazardous or problematic compounds from bulk fluid streams, typically hydrogen sulfide (H2S). H2S removal is critical to prevent expensive infrastructure damage and ensure compliance with environmental and safety regulations.

BETE spray nozzles atomize and distribute the neutralizing liquid into the process stream, increasing the reaction surface area for H2S and other problematic compounds in the pipeline.

Chemical Processing Brochure

Download PDF

石化加工手册

Download PDF

Spray Lance Injector Solution for Chemical Processing Case Study

Download PDF

Important factors to consider:

Inhibitor density and viscosity

Process pipe/vessel size, velocity, pressure, temperature, and fluid composition

Available installation ports and required clearance diameters

- In general process piping applications, a minimum of 3-5 pipe diameters of straight length upstream and 5-10 pipe diameters of straight length downstream are recommended to ensure spray dispersion

Required materials of construction for corrosive environments

Ease of maintenance/replacement

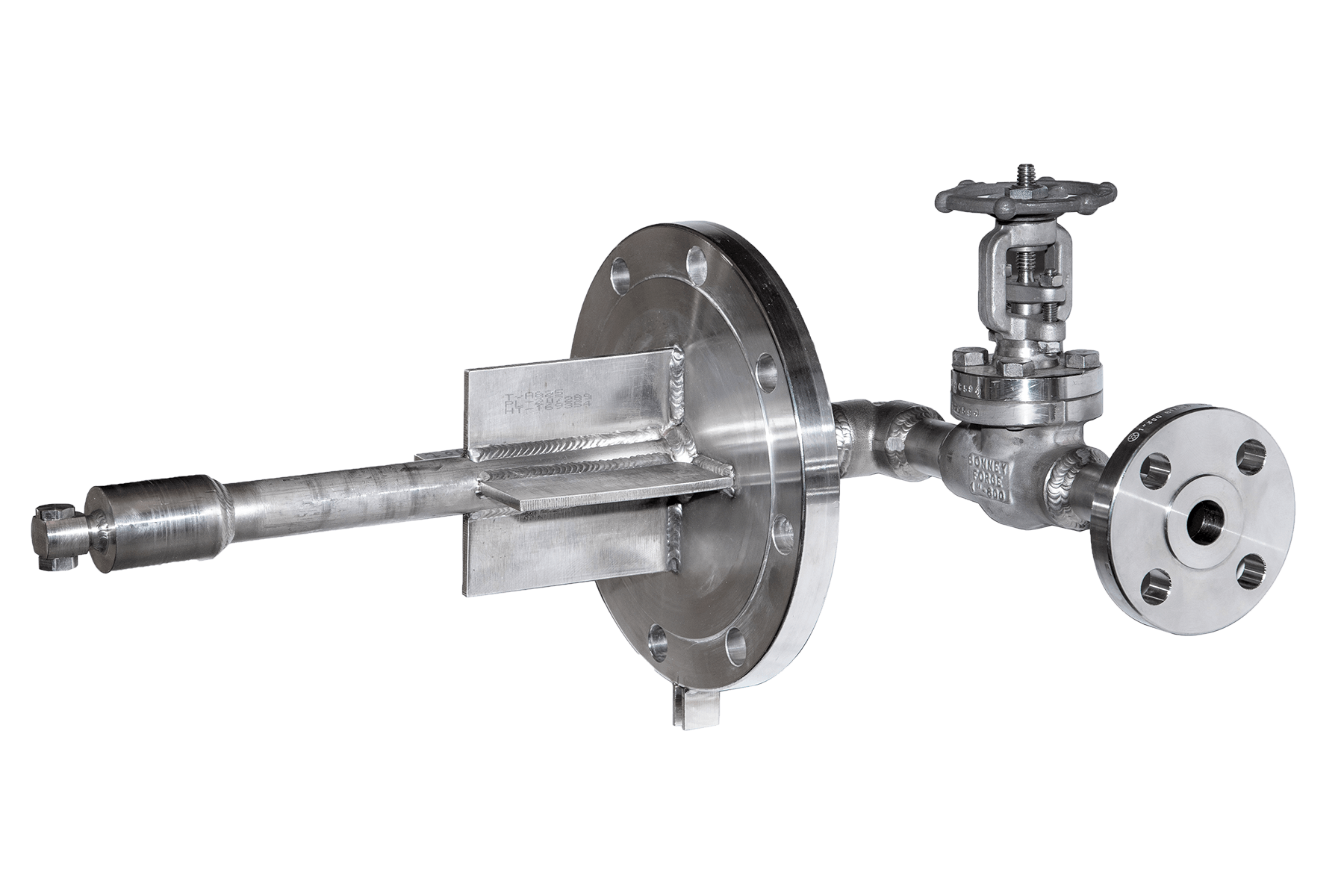

- Retractable lances allow for quill/lance removal while leaving the process online

Required inhibitor flow rate

Available pressure drop (∆P) across the nozzle

- ∆P = supply pressure at nozzle inlet – process pressure outside nozzle

Availability of steam, compressed air, nitrogen, or other carriers/atomization gases