Washing is the process of distributing water or other cleaning fluids over a product or surface to remove contaminants. Nozzles can significantly improve this washing process by providing a directed spray over the target area. This uniform spray coverage provides consistent and repeatable results, maximizing the impact and use of the cleaning media. High volumes of cleaning fluids or high operating pressures are used to maximize the impact of the washing process for hard-to-clean residues.

Soils are classified into three categories, narrowing down the type of cleaning/washing nozzle to consider for your application. The following information should be used as a recommendation intended to make it easier to choose the right nozzle.

Soil Classifications

Class 1 – Light Soil

Examples: Powder mixers, abrasive powder mixing, liquid chemicals, fruit & vegetable product

- Soil is liquid residue or light powder and not anchored to the surface, can be easily wiped away.

- Spray impact is not a significant factor.

Class 2 – Moderate Soil

Examples: Conveyor belts, machine parts, oils, paints, adhesives, cooking kettles, and fermentation tanks

- Soil is anchored to the surface or product

- Strategy of impact, temperature, and chemicals necessary to remove soil

- Repeated wetting, impact, and some chemicals required to remove soils

- Wash and rinse application

Class 3 – Heavy Soil

Examples: Paints, varnish, asphalt, molasses, printing inks, tars, heavy chemicals

- Soil is heavily caked-on surface

- Longer dwell time aids in the cleaning process

- Spray impact breaks soil off surface

- Solid jet streams are commonly used

Food & Beverage Processing Brochure PDF

Download PDF

Important factors to consider:

Size, area, or shape

Application details and requirements

- Residue to be removed

- Temperature and chemical composition of wash fluid

- Required materials of construction for corrosive residues and spray media

- Interior vs. exterior wash

- Interior: Available bottle opening sizes

- Exterior: Available nozzle mounting locations

Available/required flow rate

- Achieve effective washing while minimizing costs of treating or disposing of wastewater

Available pressure drop (∆P) across the nozzle

- ∆P = supply pressure at nozzle inlet – process pressure outside nozzle

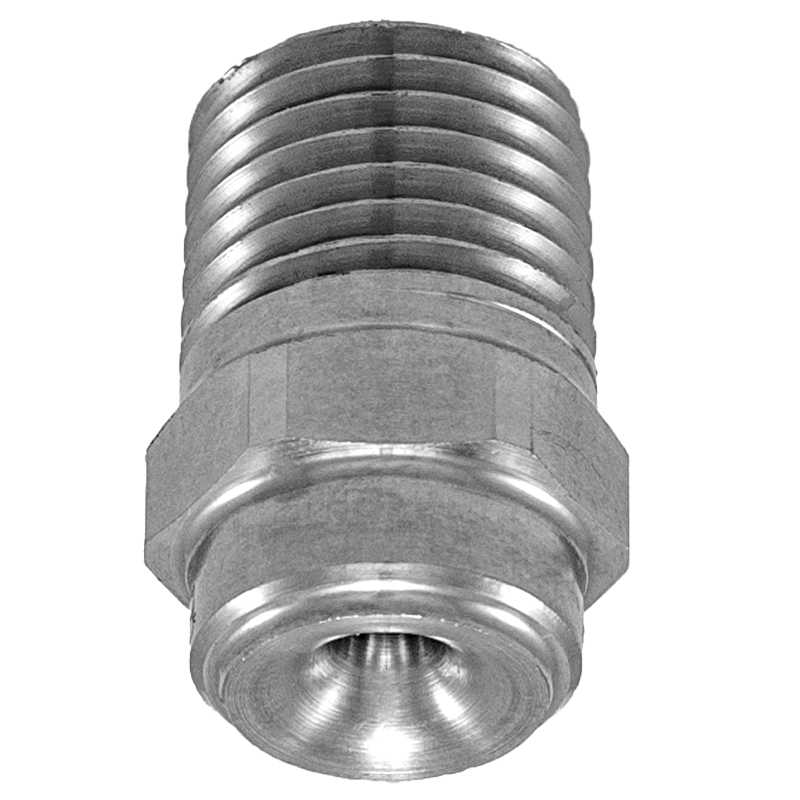

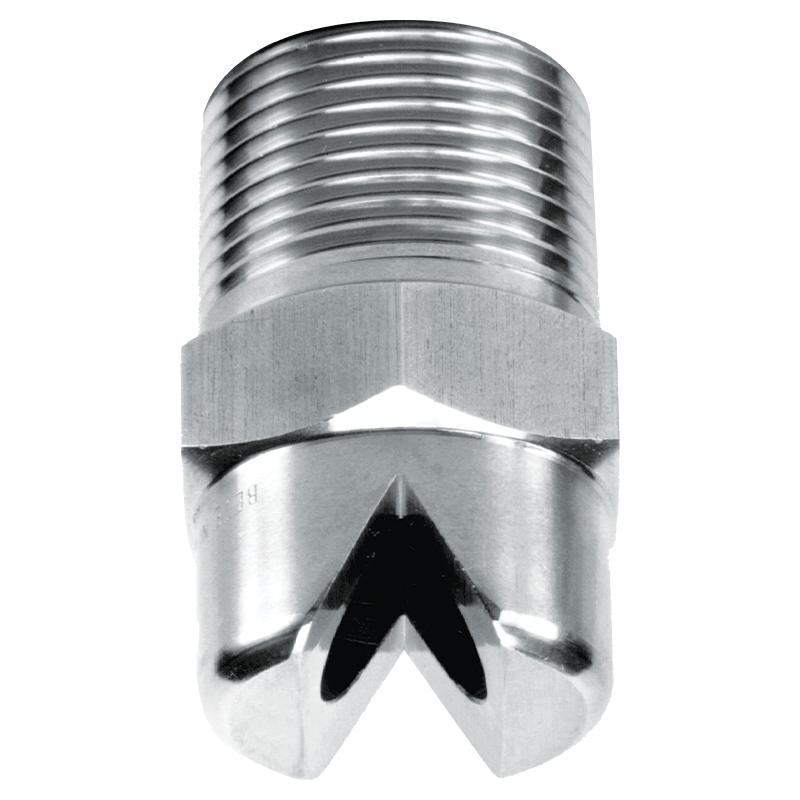

Recommended Nozzles