188金宝搏正网喷嘴清洁应用

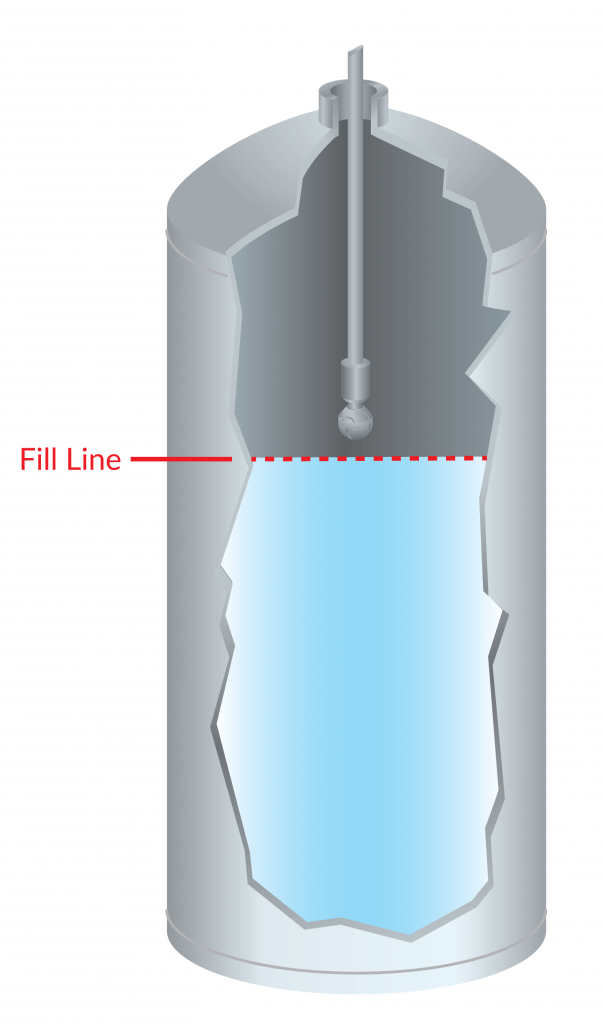

坦克清洁是许多工业应用中的重要过程,如果没有正确的解决方案,则可以耗时且昂贵。储罐,工艺容器,反应堆和工艺设备在所有行业的范围和规模上可能会有很大差异。但是,大多数坦克必须在确保卫生并防止产品污染之前清洁。

储罐清洁喷嘴可以通过确保正确分配清洁介质并最大程度地利用系统的可用流量和系统压力来帮助最大化清洁应用的效率,从而降低操作和处置成本。他们可以提供大量的时间和节省金钱,以提供其他清洁选项,例如“填充和排水”或手动输入(尤其是在危险环境中)。

常见的应用程序

Bright Beer Tanks

Brew Kettles

发酵罐

搅拌机

烹饪水壶

大型商业烤箱和冰柜

反应堆

Process Vessels

Underground Storage Tanks (UST) and Above Ground Storage Tanks (AST)

油气储罐

为您的应用选择合适的储罐清洁喷嘴有几个因素需要考虑。该信息应用作建议,以使选择正确的喷嘴更容易。

坦克清洁考虑

Soil Classifications

Soils are classified into three categories, which correlate with the type of operating principle and tank cleaning nozzles. Once you identify the type of soil being removed, you can determine which tank cleaning nozzles to select from.

1类 - 轻质土壤,易于去除

Soil is liquid residue or light powder that is not anchored to the surface and can be easily wiped away. Spray impact is not a significant factor.

Class 2 - Moderate Soil, Medium Wash

Soil is anchored to the surface. The strategy of repeated spray impact, temperature, and chemicals are necessary to remove these types of moderate soils.

3类 - 沉重的土壤,难以清洁

Soil is heavily caked on the surface. A longer dwell time is required to aid in the cleaning process. Spray impact is critical and solid jet streams are commonly used for soil removal.

Types of Operating Principles

STATIONARY

1类 - 土壤分类

Stationary nozzles, also known as static nozzles, have no moving parts. The low-maintenance designs of our innovative HydroClaw and spiral TW provide sizable free passage superior to standard static spray balls. The versatile size range and narrow form of the TW series ensure compatibility with small vessel openings.

相关产品

反动力

第2类 - 土壤分类

These are fluid-driven tank cleaning nozzles use the reaction force of the spray media to drive the rotation of the nozzle head. These provide complete 360° coverage and efficient cleaning through impact and repetition. Rotating nozzles increase tank washing efficiency over static spray balls, saving time and money by reducing water and cleaning agent consumption, while decreasing downtime.

旋转喷气机

Class 3 –Soil Classification

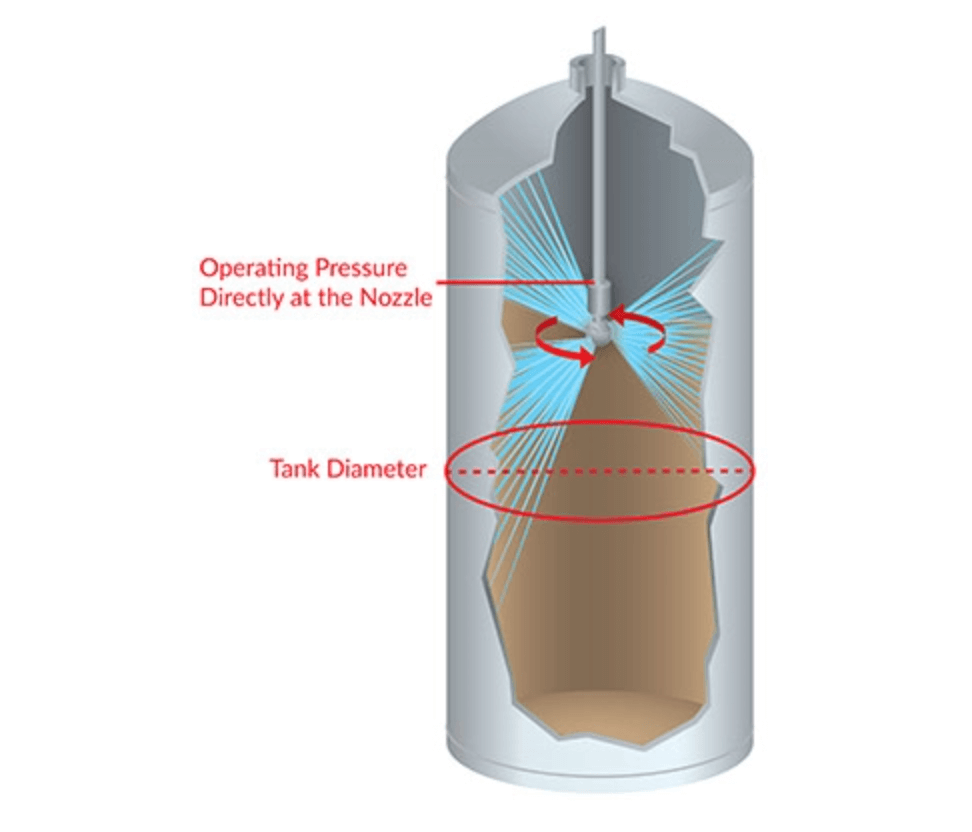

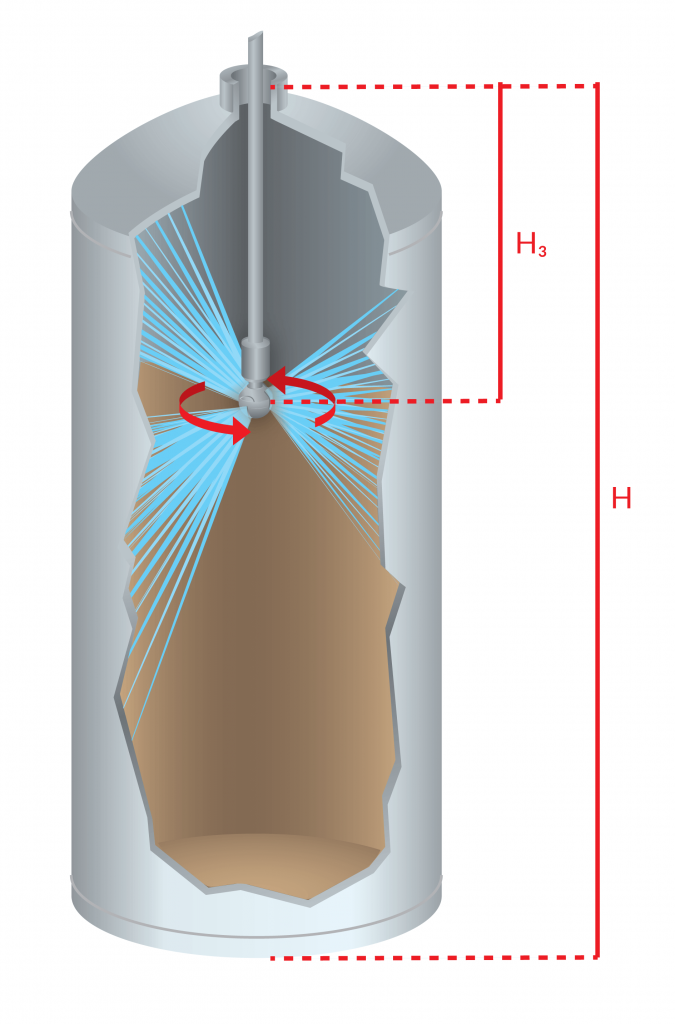

Rotary jets use the spray media flowing through internal gears on the body to rotate sets of high impact jet nozzles through an efficient 2-axis orbital pattern, providing complete 360° coverage. The jet pattern nozzles utilized on these assemblies provide significantly more impact and impingement force than other styles of tank cleaning nozzles, making them ideal for hard-to-clean residues and larger vessels.

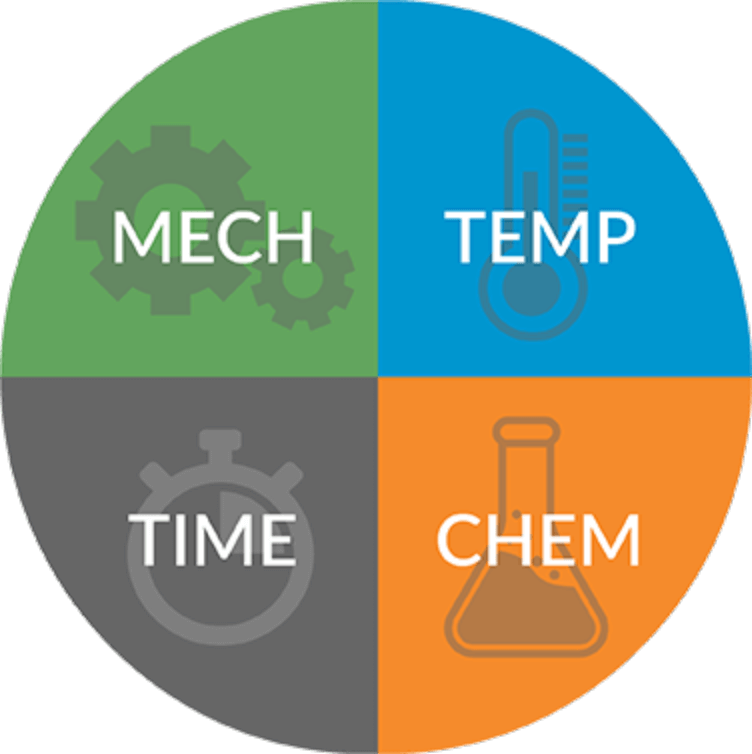

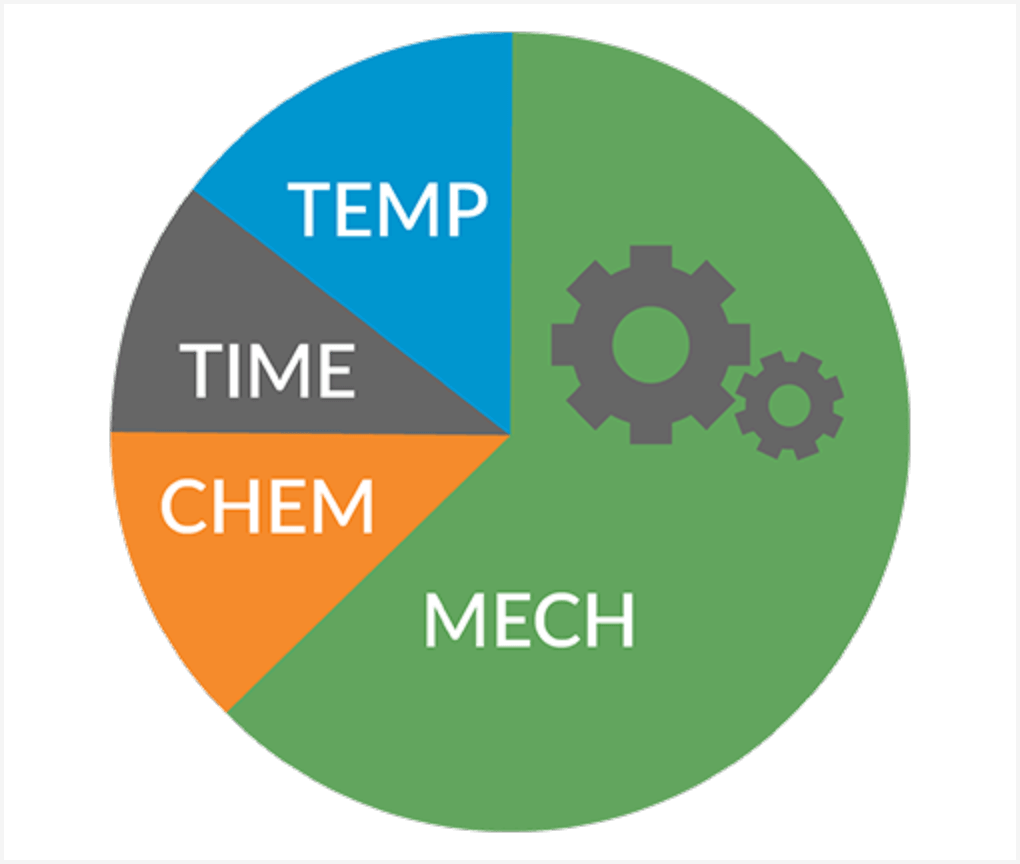

机械清洁动作

The fundamentals of cleaning technology uses the relationship between time, temperature, chemical action, and mechanical force.

机械力

The amount of spray impact applied to the surface area by the spray device

时间

通过结合机械力温度和化学作用来清洁储罐所需的持续时间

温度

进行清洁的温度

化学作用

Effect of chemical solutions or possibly hot water to aid in dissolving eroding soils on the tank surface

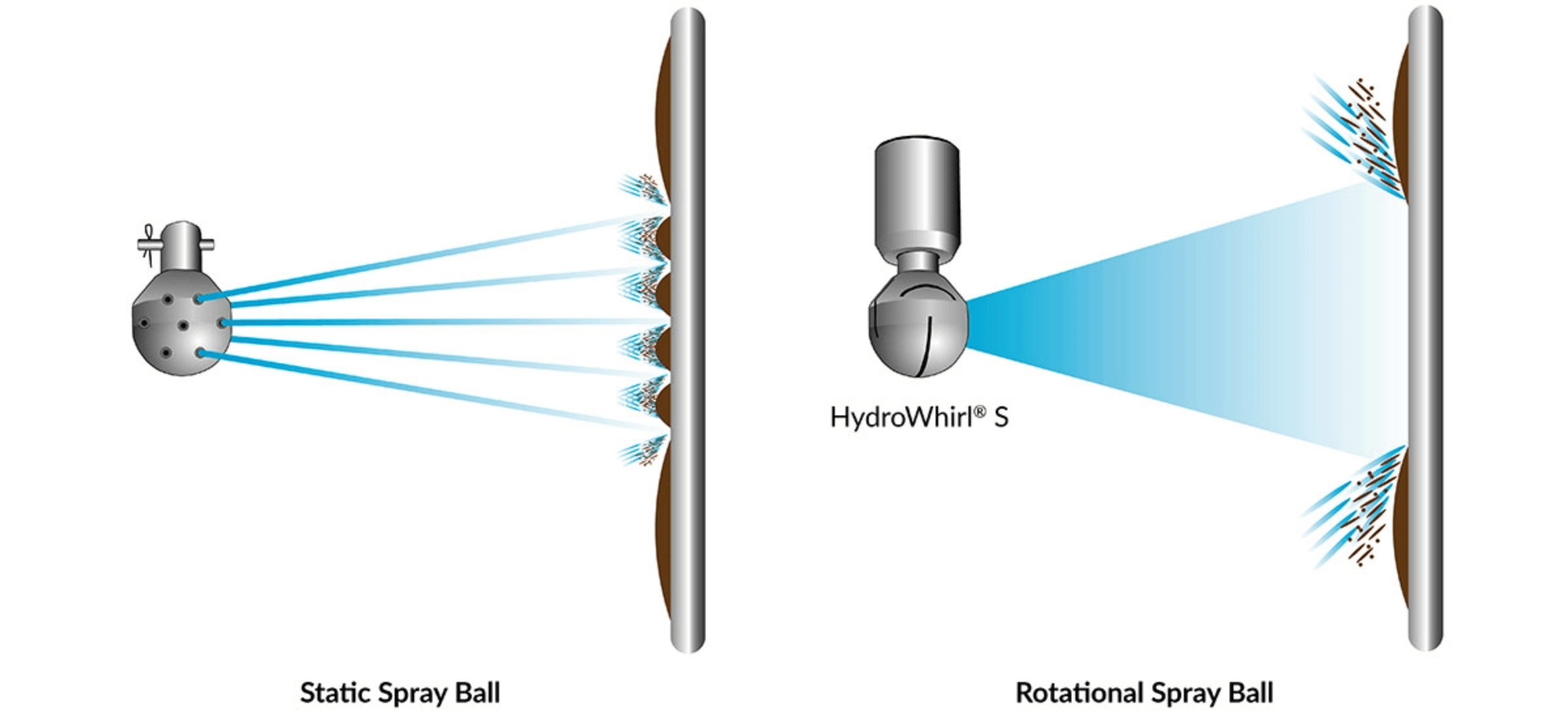

静态与旋转喷雾

Static spray devices create voids, where no cleaning action occurs and because more time is needed for cleaning, more water and solvents are used. Rotational spray devices cover more surface area and require less time for cleaning, reducing water and solvent consumption usage.

Efficient Cleaning & Cost Savings With Rotational Spray Devices

一种索引,流体驱动的设备,可优化压力和流动,从而产生高冲击力清洁喷气机,从而产生机械力,从而系统地扫整个水箱的整个表面。下图是节省时间,温度和化学物质的更大机械力的影响,节省了水分消耗和生产时间。

更大的机械力将降低化学物质,时间和温度。

Planning Guide For Precise Tank Cleaning

There are several factors to consider when selecting the right tank cleaning nozzle for your cleaning application. The following guidelines should be kept in mind when planning. BETE has decades of experience with cleaning tanks and continues to improve spray performance with new and improved nozzle technology. Our engineering spray experts can evaluate your new or existing process to recommend solutions for achieving optimal cleaning performance and reliability.

TANK SIZE

Tanks come in various sizes and shapes. Choosing the right tank cleaning device depends on thetype of soil being清洁和tank diameter.

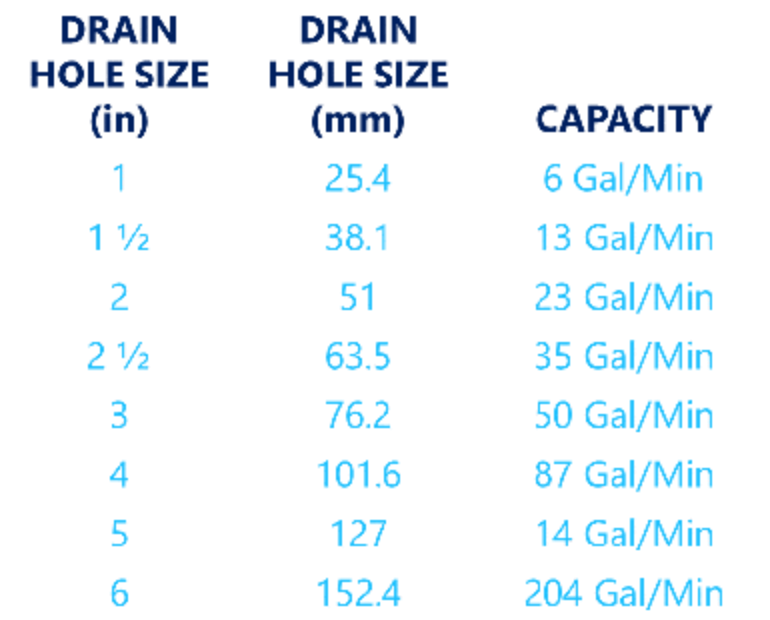

DRAIN HOLE SIZE

应选择按重力速率排水以防止在清洁过程中液体上升。确保排水管可以处理放入水箱中的任何音量。

SPRAY SHADOWS

Agitators, baffles, and pipes prevent the areas behind them from being reached directly by the spray. For this reason, more than one nozzle must be installed inside the tank. The nozzles should be positioned for the sprays to overlap, so that they can effectively clean the tank.

RESOURCES

Bete Hyledoclaw酒庄清洁解决方案案例研究

Download PDF

BETE HydroClaw Tomato Processing Case Study

Download PDF

BETE HydroWhirl Poseidon Chemical Processing Tanks Case Study

Download PDF

氢球形化学处理案例研究

Download PDF

Bete Hydrowhirl Orbitor 100马铃薯片调味案例研究

Download PDF

HydroClaw Tank Cleaning Solution for Brewery Lauter Tun Case Study

Download PDF

HWO Water Storage Tank Cleaning Case Study

Download PDF

设备和坦克洗手册

Download PDF

SI/METRIC Equipment & Tank Washing Brochure

Download PDF