Consider the FlexFlow for any food process where expensive compounds or ingredients need to be sprayed directly onto the process target. Each control panel can be used as a standalone system –or upgraded to the 2000 model to integrate with your existing plant operations.

常见的应用程序

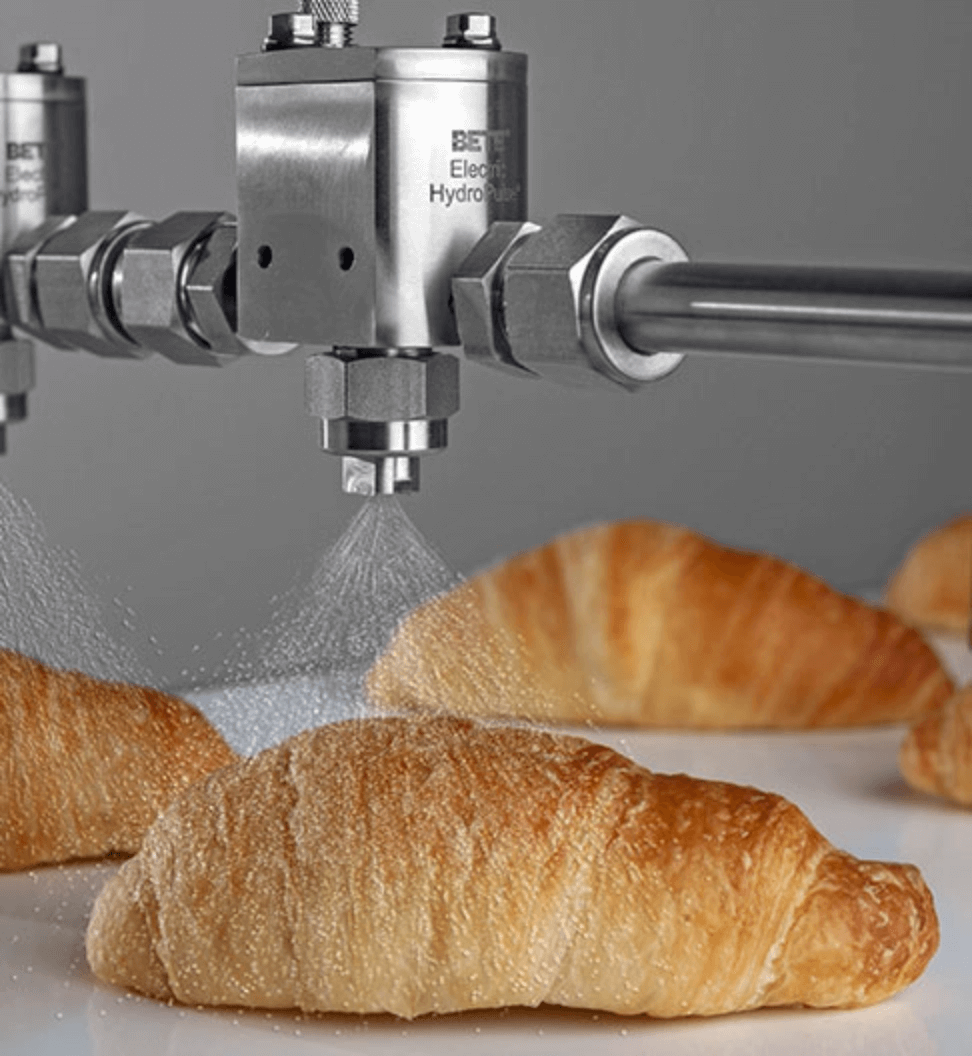

Application Of Antimicrobial Agents For Food Safety

Apply Water To Balance Moisture Loss From Frozen Products

Apply Flavors, Oil, And Butter To Enhance The Appearance And Taste Of Products

Apply Viscous Coatings Like Syrups And Glazes

Design Features

HMI touch screen includes intuitive operations for streamlined control. and diagnostic overview for troubleshooting.

Operate up to 12 nozzles.

Two zones of precision control:

- Operate up to 6 nozzles in each zone

- Zones 1 and 2 can be programmed with independent or synchronous settings

Design Features

HMI touch screen includes intuitive operations for streamlined.

Control and diagnostic overview for troubleshooting.

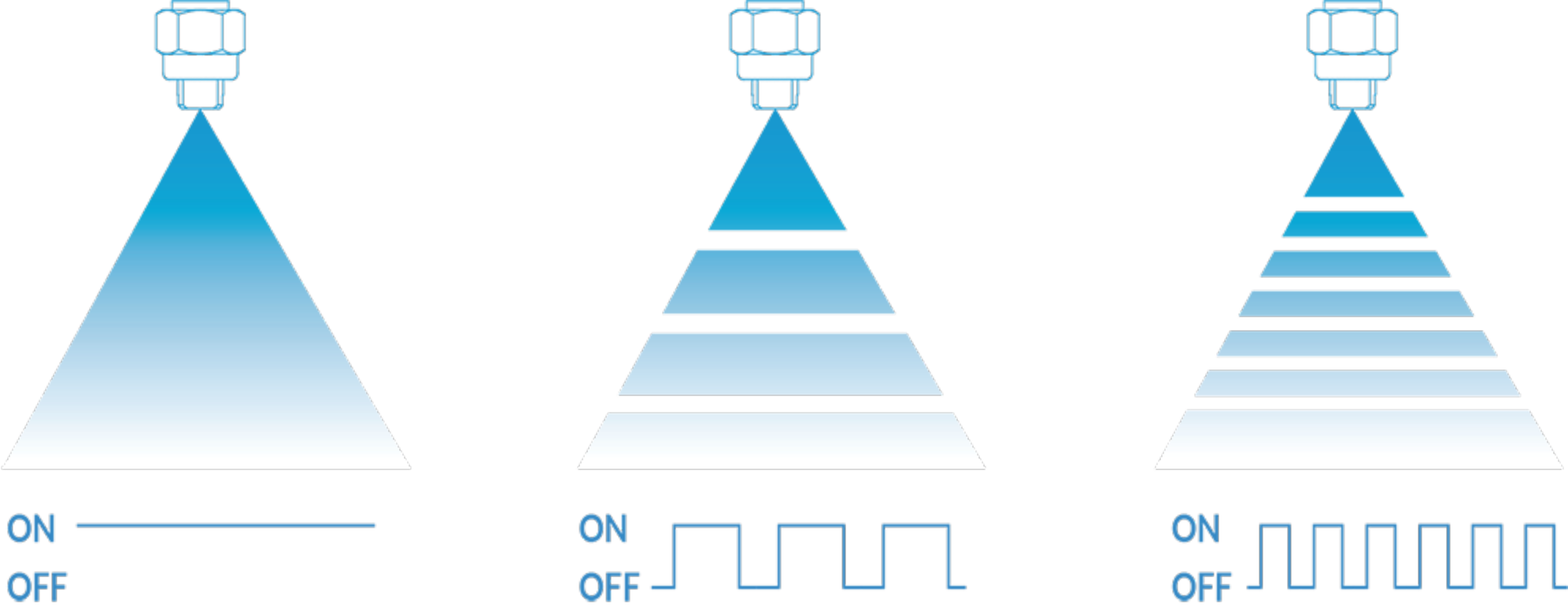

Match spray volume to conveyor speed with an auto-adjust duty cycle.

Ethernet port for process integration.

Extremely flexible in zone operations –can operate up to 20 nozzles with up to 20 triggers in up to 20 zones.

Three versions are available with an easy upgrade path:

- Model 2010 operates up to 10 nozzles

- Model 2016 operates up to 16 nozzles

- Model 2020 operates up to 20 nozzles

ADDITIONAL FEATURES AND UPGRADES

Electronic Spray Control Pulse Width Modulation (PWM)

HUMAN-MACHINE INTERFACE

A touchscreen Human Machine Interface (HMI) allows users to configure the spray system and adjust spray parameters through an easy-to-navigate menu of options. Adjustable parameters for each spray zone include nozzle cycle rate, duty cycle, trigger signal delays, and trigger state.

一个电缆腺体板斯坦dard with every FlexFlow control panel. Only pierce as many openings as needed through the membrane for easy access to field wiring.

Approvals & Certifications

- UL/ULC APPROVED

- CE APPROVED

Resources

Automated Systems for Precision Control Brochure

Food Processing Brochure

FlexFlow catalog datasheet

FlexFlow EHP Frozen Pastries Processing Case Study

FlexFlow EHP Cracker Manufacturing Case Study